Alphas-V (TD) Service Suspension

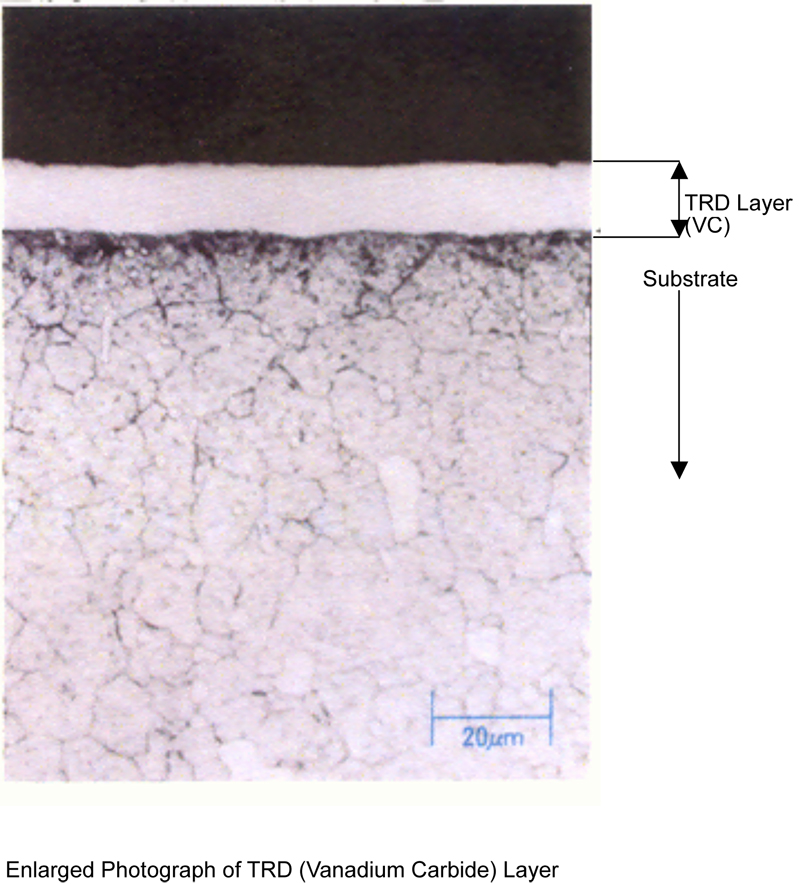

ALPHAS-V utilizes the thermal reactive diffusion process and deposits a solid vanadium carbide layer. This process improves the surface property, Anti-Wear, Anti-Galling and Anti-Seizure problems that are primary issues for Tooling industries or Stamping facilities.

ALPHAS-V is internationally known as the Toyota Diffusion Process, or TD process, developed in the Toyota Central Research and Development Lab Inc. in Japan. The superior coating properties of the ALPHAS-V (TD) process have been proven in many different industries for decades, and the TD process still is considered to be the best coating process.

The ALPHAS-V coating process is metallurgically bonded through diffusion and is a tight and strong adhesion to the substrate steel, which offers exceptional flaking resistance. Due to the hardness and thicker deposition, the dense and pure structure, ALPHAS-V provides unparalleled properties and contributes to a significant extension of the lifespan of tools and dies.

Characteristics

|

Coating |

VC- Vanadium Carbide |

|

Hardness |

3200-3500 Vickers (Approx. HRC 95-100) |

|

Thickness |

4-5µm for cutting, 5-8µm for forming, die casting etc. |

|

Surface |

Dense, Non-Porous |

|

Oxidation Temp |

Approx 1250°F |

|

Coefficient Friction |

0.29 (but it is improved by base roughness) |

|

Adhesive Tendency |

Low affinity against other metals |

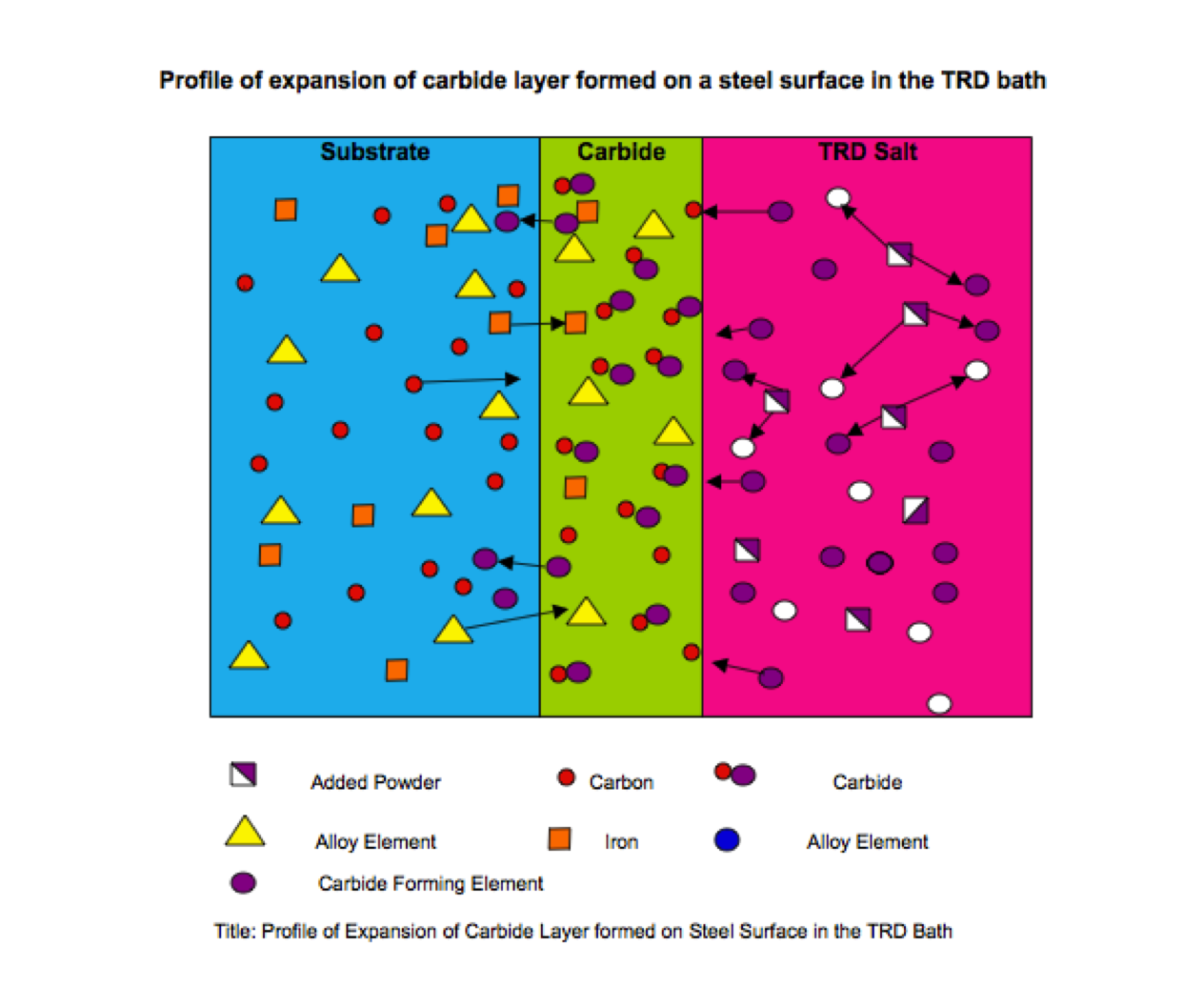

Atoms or ions of carbide constituents dispersed in the salt bath combines with C atoms conained in the substrate; then the carbide layer is formed on the surface of the substrate. Thereafter, the layer is expanded by reaction between C and the carbide constituent on the formed carbide layer and the continuous supply of C atoms from the substrate.

Recommended Substrate Materials for ALPHAS-V (TD)

1. DCMX-Matrix Type Tool Steel distributed by International Mold Steel

Application Data

|

Cold Forging

|

Cutting

|

Die Casting

|

|

Extrusion

|

Hot Forging

|

Machine Component

|

|

Metal Stamping

|

Metal Stamping - Pierce Punch

|

Mold

|

|

Other

|

Roll Forming

|

Shearing

|

Galleries

Alphas-V Example Gallery

D2(SKD11)

MATERIAL-DC53

D2(SKD11)

H13 (SKD61)

D2(SKD11)

DC53

D2(SKD11)

D2(SKD11)

D2(SKD11)

DC53

DCMX-DAIDO

.jpg)

DCMX-DAIDO

Facts and Data

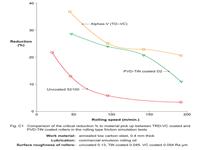

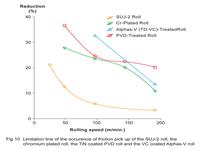

Rolling Speed

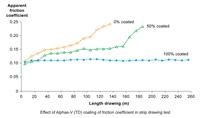

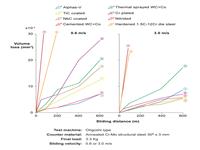

Strip Drawing Friction

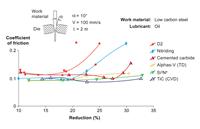

Friction

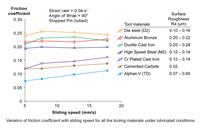

Friction Sliding

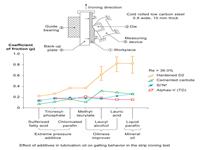

Galling Behavior

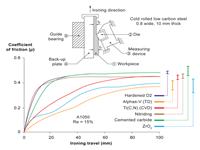

Ironing Friction

Rolling Speed

Rolling Speed Diagram

Sliding

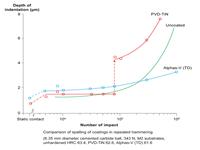

Spalling

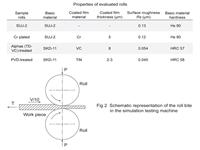

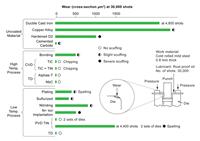

Table III

Table III 2

Wear

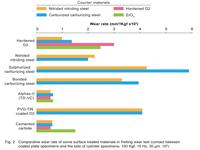

Wear Rate

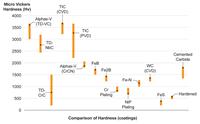

Micro Vickers Hardness - ALPHAS-V